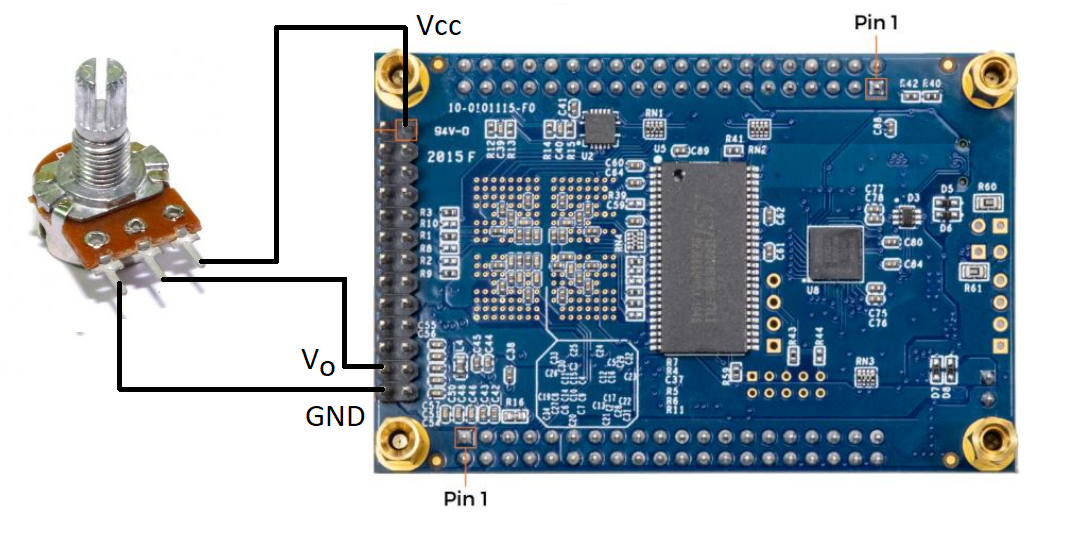

In this tutorial, we are going to use DE0-Nano to read the voltage across a potentiometer. Then DE0-Nano will send data to Raspberry Pi 4B.

Step 1: Connect the potentiometer to DE0-Nano

Step 2: Open the ADC example

e.g. C:\DE0\DE0-Nano_v.1.2.8_SystemCD\Demonstration\DE0_NANO_ADC

Make sure that the ADC and GPIO ports are included in the Pin Planner

Step 3: Edit the DE0-Nano.v as follows. The GPIO_0[10:3] will be used to communicate to Raspberry Pi later.

module DE0_NANO(

//////////// CLOCK //////////

CLOCK_50,

//////////// LED //////////

LED,

//////////// KEY //////////

KEY,

//////////// SW //////////

SW,

//////////// SDRAM //////////

DRAM_ADDR,

DRAM_BA,

DRAM_CAS_N,

DRAM_CKE,

DRAM_CLK,

DRAM_CS_N,

DRAM_DQ,

DRAM_DQM,

DRAM_RAS_N,

DRAM_WE_N,

//////////// EPCS //////////

EPCS_ASDO,

EPCS_DATA0,

EPCS_DCLK,

EPCS_NCSO,

//////////// Accelerometer and EEPROM //////////

G_SENSOR_CS_N,

G_SENSOR_INT,

I2C_SCLK,

I2C_SDAT,

//////////// ADC //////////

ADC_CS_N,

ADC_SADDR,

ADC_SCLK,

ADC_SDAT,

//////////// 2x13 GPIO Header //////////

GPIO_2,

GPIO_2_IN,

//////////// GPIO_0, GPIO_0 connect to GPIO Default //////////

GPIO_0,

GPIO_0_IN,

//////////// GPIO_1, GPIO_1 connect to GPIO Default //////////

GPIO_1,

GPIO_1_IN

);

//////////// CLOCK //////////

input CLOCK_50;

//////////// LED //////////

output [7:0] LED;

//////////// KEY //////////

input [1:0] KEY;

//////////// SW //////////

input [3:0] SW;

//////////// SDRAM //////////

output [12:0] DRAM_ADDR;

output [1:0] DRAM_BA;

output DRAM_CAS_N;

output DRAM_CKE;

output DRAM_CLK;

output DRAM_CS_N;

inout [15:0] DRAM_DQ;

output [1:0] DRAM_DQM;

output DRAM_RAS_N;

output DRAM_WE_N;

//////////// EPCS //////////

output EPCS_ASDO;

input EPCS_DATA0;

output EPCS_DCLK;

output EPCS_NCSO;

//////////// Accelerometer and EEPROM //////////

output G_SENSOR_CS_N;

input G_SENSOR_INT;

output I2C_SCLK;

inout I2C_SDAT;

//////////// ADC //////////

output ADC_CS_N;

output ADC_SADDR;

output ADC_SCLK;

input ADC_SDAT;

//////////// 2x13 GPIO Header //////////

inout [12:0] GPIO_2;

input [2:0] GPIO_2_IN;

//////////// GPIO_0, GPIO_0 connect to GPIO Default //////////

output [33:0] GPIO_0;

input [1:0] GPIO_0_IN;

//////////// GPIO_1, GPIO_1 connect to GPIO Default //////////

inout [33:0] GPIO_1;

input [1:0] GPIO_1_IN;

wire wSPI_CLK;

wire wSPI_CLK_n;

reg [33:0] GPIO_0;

reg [7:0] PWM_adj;

reg [8:0] PWM_width;

//=======================================================

// Structural coding

//=======================================================

SPIPLL U0 (

.inclk0(CLOCK_50),

.c0(wSPI_CLK),

.c1(wSPI_CLK_n)

);

ADC_CTRL U1 (

.iRST(KEY[0]),

.iCLK(wSPI_CLK),

.iCLK_n(wSPI_CLK_n),

.iGO(KEY[1]),

.iCH(SW[2:0]),

.oLED(LED),

.oDIN(ADC_SADDR),

.oCS_n(ADC_CS_N),

.oSCLK(ADC_SCLK),

.iDOUT(ADC_SDAT)

);

always @(posedge CLOCK_50)

begin

GPIO_0[10:3] <= LED[7:0];

end

endmodule

Step 4: As "Analog_In0" is used, adjust the DIP switch as follows

Step 5: Compile and upload the sof file via the "Programmer" option. Then press the Key Button 1 in DE0-Nano. When the potentiometer is rotated, the onboard LED should light up accordingly.

Step 6: Use 8 female jumper wires to connect DE0-Nano to Raspberry Pi 4B.

DE0-Nano <=> RPi 4B

GPIO_0[3] <=> GPIO 17

GPIO_0[4] <=> GPIO 27

GPIO_0[5] <=> GPIO 22

GPIO_0[6] <=> GPIO 23

GPIO_0[7] <=> GPIO 24

GPIO_0[8] <=> GPIO 25

GPIO_0[9] <=> GPIO 16

GPIO_0[10] <=> GPIO 26

Step 7: Prepare an 8-bit truth table

You may open excel and set A1, B1, C1, D1, E1, F1, G1, H1 cells to 0.

Type the following formula in H2 cell.

=IF(MOD(ROW()-ROW($H$1),POWER(2, ((COLUMN() - COLUMN($H$1)) * -1) + 1)) >= (POWER(2, ((COLUMN() - COLUMN($H$1)) * -1) + 1) / 2),1,0)

Drag the "+" logo from H2 cell to the others.

Copy the 2048 elements in truth table and save the file as "8bit_truthtable.txt"

Step 8: Write Python code in Raspberry Pi.

import RPi.GPIO as GPIO

import time

binary=[0]*256;

with open("8bit_truthtable.txt") as f:

data = f.readlines();

for i in range(0,256):

binary[i] = data[i].split();

pinA=26; #the most significant bit

pinB=16;

pinC=25;

pinD=24;

pinE=23;

pinF=22;

pinG=27;

pinH=17; #the least significant bit

for i in range(8):

globals()[f'diff{i}']=[0]*256;

GPIO.setmode(GPIO.BCM)

GPIO.setwarnings(False)

GPIO.setup(pinA,GPIO.IN)

GPIO.setup(pinB,GPIO.IN)

GPIO.setup(pinC,GPIO.IN)

GPIO.setup(pinD,GPIO.IN)

GPIO.setup(pinE,GPIO.IN)

GPIO.setup(pinF,GPIO.IN)

GPIO.setup(pinG,GPIO.IN)

GPIO.setup(pinH,GPIO.IN)

while True:

A = GPIO.input(pinA)

B = GPIO.input(pinB)

C = GPIO.input(pinC)

D = GPIO.input(pinD)

E = GPIO.input(pinE)

F = GPIO.input(pinF)

G = GPIO.input(pinG)

H = GPIO.input(pinH)

#Subtracted ADC reading by each of the row in truth table.

#If these two values the same, the digital level is marked and compared

for i in range(0,256):

diff0[i] = A-int(binary[i][0]);

diff1[i] = B-int(binary[i][1]);

diff2[i] = C-int(binary[i][2]);

diff3[i] = D-int(binary[i][3]);

diff4[i] = E-int(binary[i][4]);

diff5[i] = F-int(binary[i][5]);

diff6[i] = G-int(binary[i][6]);

diff7[i] = H-int(binary[i][7]);

if(diff0[i]==0 and diff1[i]==0 and diff2[i]==0 and diff3[i]==0 and diff4[i]==0 and diff5[i]==0 and diff6[i]==0 and diff7[i]==0):

print(i);

time.sleep(0.1);

Step 9: Press F5 to run the Python script. When the potentiometer is rotated, the digital reading should vary between 0 and 255.

Comments

Post a Comment