In this tutorial, we are going to write Verilog code to read the accelerometer along the x and y-axis in FPGA (DE0-Nano). A LED and 220-ohm resistor are connected through a GPIO port. When you rotate the FPGA, the light intensity of the LED should vary continuously.

|

| Terasic |

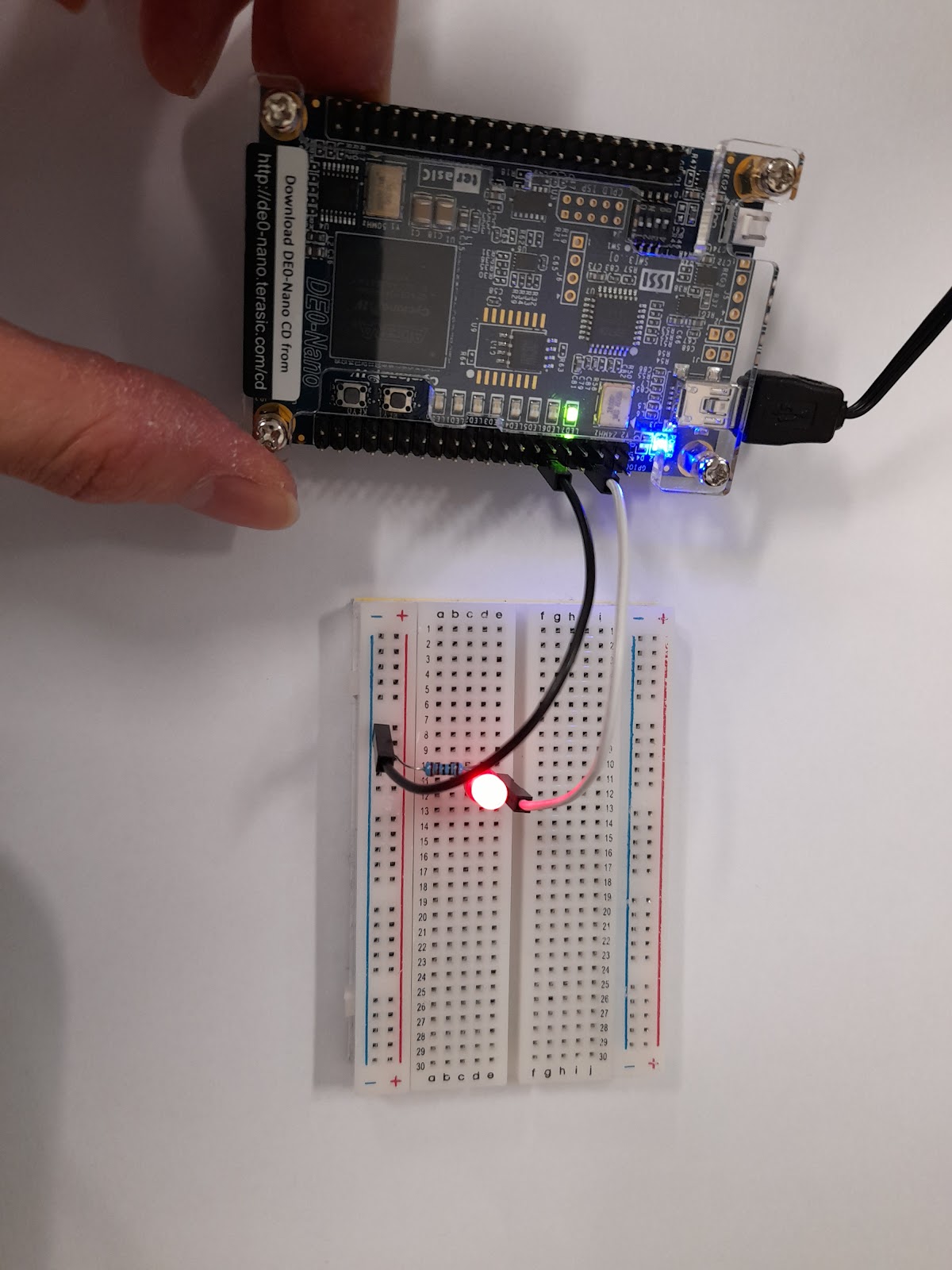

Step 1: Build the circuit below

Step 2: Open the example "DE0_NANO_GSensor" in Terasic CD. Follow the DE0-Nano_User_Manual.pdf to add the GPIO_0_D and GPIO_0_IN in the pin planner.

Step 3: Paste the following code to DE0-NANO.v

module DE0_NANO(

//////////// CLOCK //////////

CLOCK_50,

//////////// LED //////////

LED,

//////////// KEY //////////

KEY,

//////////// Accelerometer and EEPROM //////////

G_SENSOR_CS_N,

G_SENSOR_INT,

I2C_SCLK,

GPIO_0_D,

GPIO_0_IN,

I2C_SDAT

);

//////////// CLOCK //////////

input CLOCK_50;

//////////// LED //////////

output [7:0] LED;

//////////// KEY //////////

input [1:0] KEY;

//////////// Accelerometer and EEPROM //////////

output G_SENSOR_CS_N;

input G_SENSOR_INT;

output I2C_SCLK;

inout I2C_SDAT;

inout [33:0] GPIO_0_D;

input [1:0] GPIO_0_IN;

//=======================================================

// REG/WIRE declarations

//=======================================================

wire dly_rst;

wire spi_clk, spi_clk_out;

wire [15:0] data_x;

wire [15:0] data_y;

wire [15:0] data_z;

reg [7:0] GPIO_0_D;

//=======================================================

// Structural coding

//=======================================================

//Reset

reset_delay u_reset_delay (

.iRSTN(KEY[0]),

.iCLK(CLOCK_50),

.oRST(dly_rst));

// PLL

spipll u_spipll (

.areset(dly_rst),

.inclk0(CLOCK_50),

.c0(spi_clk), // 2MHz

.c1(spi_clk_out)); // 2MHz phase shift

// Initial Setting and Data Read Back

spi_ee_config u_spi_ee_config (

.iRSTN(!dly_rst),

.iSPI_CLK(spi_clk),

.iSPI_CLK_OUT(spi_clk_out),

.iG_INT2(G_SENSOR_INT),

.oDATA_L(data_x[7:0]), //higher sensitivity

oDATA_L(data_x[10:0],oDATA_H(data_x[15:11]) tune

.oDATA_H(data_x[15:8]),

.SPI_SDIO(I2C_SDAT),

.oSPI_CSN(G_SENSOR_CS_N),

.oSPI_CLK(I2C_SCLK));

//LED

led_driver u_led_driver (

.iRSTN(!dly_rst),

.iCLK(CLOCK_50),

.iDIG(data_x[9:0]),

.iG_INT2(G_SENSOR_INT),

.oLED(LED));

always @(posedge CLOCK_50)

begin

if(LED[3]!=1'b0 && LED[4]!=1'b0) //tilt x-axis

GPIO_0_D[3] <= 1'b0;

else

GPIO_0_D[3] <= 1'b1;

end

endmodule

Step 4: Paste the following code to spi_ee_config.v

module spi_ee_config (

iRSTN,

iSPI_CLK,

iSPI_CLK_OUT,

iG_INT2,

oDATA_L,

oDATA_H,

SPI_SDIO,

oSPI_CSN,

oSPI_CLK);

`include "spi_param.h"

//=======================================================

// PORT declarations

//=======================================================

// Host Side

input iRSTN;

input iSPI_CLK, iSPI_CLK_OUT;

input iG_INT2;

output reg [SO_DataL:0] oDATA_L;

output reg [SO_DataL:0] oDATA_H;

// SPI Side

inout SPI_SDIO;

output oSPI_CSN;

output oSPI_CLK;

//=======================================================

// REG/WIRE declarations

//=======================================================

reg [3:0] ini_index;

reg [SI_DataL-2:0] write_data;

reg [SI_DataL:0] p2s_data;

reg spi_go;

wire spi_end;

wire [SO_DataL:0] s2p_data;

reg [SO_DataL:0] low_byte_data;

reg spi_state;

reg high_byte;

reg read_back;

reg clear_status, read_ready;

reg [3:0] clear_status_d;

reg high_byte_d, read_back_d;

reg [IDLE_MSB:0] read_idle_count;

//=======================================================

// Sub-module

//=======================================================

spi_controller u_spi_controller (

.iRSTN(iRSTN),

.iSPI_CLK(iSPI_CLK),

.iSPI_CLK_OUT(iSPI_CLK_OUT),

.iP2S_DATA(p2s_data),

.iSPI_GO(spi_go),

.oSPI_END(spi_end),

.oS2P_DATA(s2p_data),

.SPI_SDIO(SPI_SDIO),

.oSPI_CSN(oSPI_CSN),

.oSPI_CLK(oSPI_CLK));

//=======================================================

// Structural coding

//=======================================================

// Initial Setting Table

always @ (ini_index)

case (ini_index)

0 : write_data = {THRESH_ACT,8'h20};

1 : write_data = {THRESH_INACT,8'h03};

2 : write_data = {TIME_INACT,8'h01};

3 : write_data = {ACT_INACT_CTL,8'h7f};

4 : write_data = {THRESH_FF,8'h09};

5 : write_data = {TIME_FF,8'h46};

6 : write_data = {BW_RATE,8'h09}; // output data rate : 50 Hz

7 : write_data = {INT_ENABLE,8'h10};

8 : write_data = {INT_MAP,8'h10};

9 : write_data = {DATA_FORMAT,8'h40};

default: write_data = {POWER_CONTROL,8'h08};

endcase

always@(posedge iSPI_CLK or negedge iRSTN)

if(!iRSTN)

begin

ini_index <= 4'b0;

spi_go <= 1'b0;

spi_state <= IDLE;

read_idle_count <= 0; // read mode only

high_byte <= 1'b0; // read mode only

read_back <= 1'b0; // read mode only

clear_status <= 1'b0;

end

// initial setting (write mode)

else if(ini_index < INI_NUMBER)

case(spi_state)

IDLE : begin

p2s_data <= {WRITE_MODE, write_data};

spi_go <= 1'b1;

spi_state <= TRANSFER;

end

TRANSFER : begin

if (spi_end)

begin

ini_index <= ini_index + 4'b1;

spi_go <= 1'b0;

spi_state <= IDLE;

end

end

endcase

// read data and clear interrupt (read mode)

else

case(spi_state)

IDLE : begin

read_idle_count <= read_idle_count + 1;

if (high_byte) // multiple-byte read

begin

if(read_idle_count%2 == 0)

begin

p2s_data[15:8] <={READ_MODE,X_HB};

end

if(read_idle_count%2 != 0)

begin

p2s_data[15:8] <={READ_MODE,Y_HB};

end

read_back <= 1'b1;

end

else if (read_ready)

begin

if(read_idle_count%2 == 0)

begin

p2s_data[15:8] <={READ_MODE, X_LB};

end

if(read_idle_count%2 != 0)

begin

p2s_data[15:8] <={READ_MODE, Y_LB};

end

read_back <= 1'b1;

end

else if (!clear_status_d[3]&&iG_INT2 || read_idle_count[IDLE_MSB])

begin

p2s_data[15:8] <= {READ_MODE, INT_SOURCE};

clear_status <= 1'b1;

end

if (high_byte || read_ready || read_idle_count[IDLE_MSB] || !clear_status_d[3]&&iG_INT2)

begin

spi_go <= 1'b1;

spi_state <= TRANSFER;

end

if (read_back_d) // update the read back data

begin

if (high_byte_d)

begin

oDATA_H <= s2p_data;

oDATA_L <= low_byte_data;

end

else

low_byte_data <= s2p_data;

end

end

TRANSFER : begin

if (spi_end)

begin

spi_go <= 1'b0;

spi_state <= IDLE;

if (read_back)

begin

read_back <= 1'b0;

high_byte <= !high_byte;

read_ready <= 1'b0;

end

else

begin

clear_status <= 1'b0;

read_ready <= s2p_data[6];

read_idle_count <= 0;

end

end

end

endcase

always@(posedge iSPI_CLK or negedge iRSTN)

if(!iRSTN)

begin

high_byte_d <= 1'b0;

read_back_d <= 1'b0;

clear_status_d <= 4'b0;

end

else

begin

high_byte_d <= high_byte;

read_back_d <= read_back;

clear_status_d <= {clear_status_d[2:0], clear_status};

end

endmodule

Step 5: Compile the code and upload the sof file via the use of "Programmer". The LED through GPIO_0_D[3] lights up when the FPGA is rotated.

Comments

Post a Comment